Bawdy Blueprints

Depth sensing

Probably the surest way to achieve depth sensing- either for a toy that penetrates or a toy that can be penetrated- is to use capacitive touch. Captouch allows detection of skin nearby, and can be tuned in sensitivity.Having captouch rings some small distance apart will give a fairly good resolution to a depth measurement, and will allow for measurements at any point around the perimeter / circumference. It would be possible to have discreet pads at distances along the length- but if a hand was interacting with the device, it may not be around the circumference and the touch may not be captured.

There is a whole world of capacitance sensing, beyond what is normally known as "captouch." At some point, an array of these sensors will provide a comprehensive view for the device on where skin is contacting it.

Of course... if a toy is interacting with another toy instead of a person with skin, these techniques may fail. But just like styluses are made today to interact with capacitive touch screens, toys can be made for this purpose.

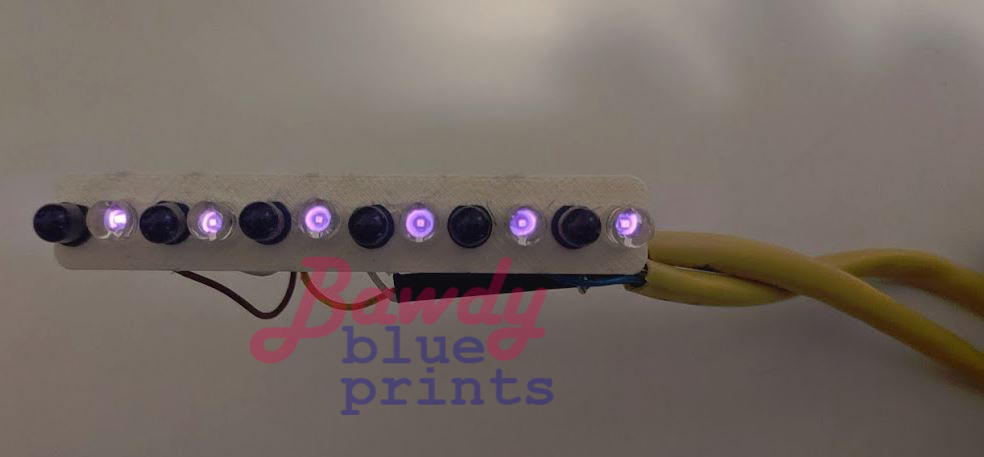

Aside from capacitive methods, depth sensing is also possible with infrared reflection. This technique does not require skin to be in contact with the device. If IR emitters and receivers are alternated, when there is something in front of an IR emitter, the light will be reflected back- so the receiver will sense a higher amount of light than when nothing is in front of it. This can be used to produce a real-time depth measurement.

The infrared is visible to cameras but not to people. (Common IR wavelengths are 850nm and 920nm. Humans can see a dull glow at 850nm when observed head-on, and nothing at all at 920nm.)

Very sloppily "installed" by pouring silicone around the LED strip. You can see that position was not fixed properly during the pour. I would also expect this to delaminate and fall apart quickly- in future revisions I would cure a silicone shell that the LEDs would go inside, rather than curing the silicone around the LEDs.

Very sloppily "installed" by pouring silicone around the LED strip. You can see that position was not fixed properly during the pour. I would also expect this to delaminate and fall apart quickly- in future revisions I would cure a silicone shell that the LEDs would go inside, rather than curing the silicone around the LEDs.

The silicone is Dragon Skin 10, and this design works- enough IR passes through the silicone to get a strong reading when the light is reflected.

The final design for this would likely be surface-mount IR LEDs on a flexible circuit.

- Akatsuki Lab has also demonstrated a proof of concept for IR depth sensing.

page last updated 20.11.19

Bawdy Blueprints on Reddit at reddit.com/r/BawdyBlueprints

Bawdy Blueprints on Twitter at twitter.com/BawdyBlueprints

email bawdyblueprints at gmail dot com